We enable constant enterprise transformation at speed and scale.

We introduce ourselves as Shell Moulded Steel and Non-Ferrous casting manufacturer with Quality System of ISO 9001:2015 Standards. 40000 sq-ft of built-up area & 2,30,850 sq-ft of open area with 500 kva power. We have an installed capacity of 6000 tons Shell Moulded Steel Casting per annum and 1200 tons for non-ferrous Casting per aunum. We have the entire necessary infrastructure for the same. We are specialized in stainless steel, Gun Metal, Phosphor Bronze and Lead Tin Bronze castings. Our company turnover is 24 crores per annum at present with 100 Employees.

Mission and Vision

Our Vision & Mission are both helping our team to achieve the goal. We identify the clients' requirements and provide the best solutions.

Our Challenges

We take pride in helping our clients deliver marvelous results when it comes to their projects. From data to performance, we’ve got you covered.

Our Team

Meet our institute leaders and the hard-working personalities who deliver innovative concepts to corporations like yours.

Four reasons why you should choose our service

Precisely machined components

Shell Moulding process

World Class Quality Components

Commitment & Customer Oriented

Casting services that Will help you grow.

Best Foundry in coimbatore!

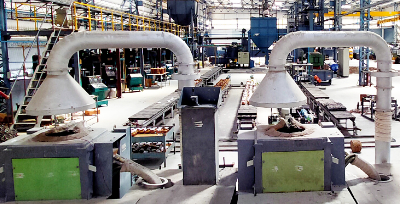

The heart of every foundry is the melting furnace in which the metal is liquefied. These furnaces use different technologies to melt the material & we use the induction furnace. An advantage of induction heating is that the heat is generated within the furnace's charge itself rather than applied by a burning fuel or other external heat source, which can be important in applications where contamination is an issue.

The thermal sand reclamation system is used to recondition, remove waste, and clean sand which is used in foundry castings. The purpose of thermal sand Reclamation systems is to reduce the need for fresh sand in foundry castings. Reuse of foundry sand is beneficial for the environment and makes sense economically.