Welcome To Bharathi Industries

Shell moulded Steel & Non-Ferrous Casting Manufacturer

About Us

Bharathi industries Established in the year of 1998, We are specializes in Shell Moulded Steel Casting. From Qualified Technocrat Mr R Jayaprakash. A high spirited entrepreneur with a focus to achieve excellence in product & development. With the vertical integration for its group requirements the company has set up a state of the art foundry, machine shop and assembly shop which enables Bharathi industries to have two verticals product manufacturing. We are experts in production of all types of automobile components, pump parts and other general engineering applications. We continue to innovate and transform to meet client's needs.

Our commitment towards Customer Delight has enabled us to become one of the leading manufacturers of a wide range of Shell Moulded Steel Castings.

To make these virtues a habit, himself on his daily actions. In a journal he drew a table with a row for every virtue and a column for every day of the week.

We also know those epic stories, those modern-day legends surrounding the early failures of such supremely successful folks as Michael Jordan and Bill Gates.

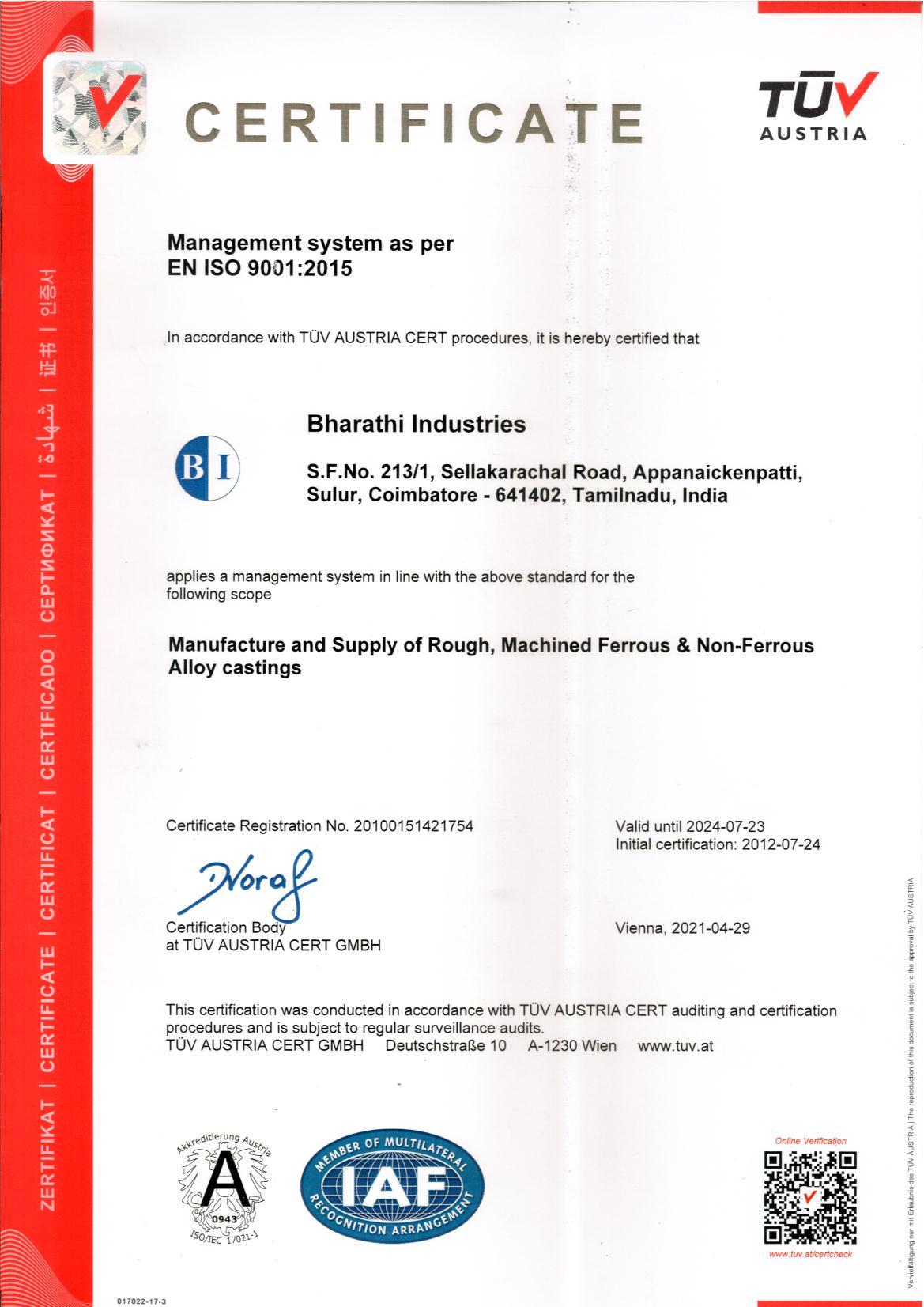

Quality Assurance

A stage wise inspection is to meet the satisfaction process conducted customer through, obtain their specification and quality of the Casting. Chemical,Mechanical and Metllurgical properties of the product is tested in-house.

Moulding Process

Shell Moulding

Current Machineries at Bharathi Industries

Positive pleasure-oriented goals are much more powerful motivators than negative fear-based ones.

- Induction Furnace - 300 kgs x 3 – 900kgs per hr

- Automatic Shell Core Shooter

- Sand Muller - 250kgs

- Sand Reclamation Plant 1 ton per hr

- Auto Pouring Track line Setup

- Spectrometer – Cu & Fe base

- Automatic Runner Cutting Machine

- Annealing furnace -500kgs x 3 – 1.5tons

- Tumb blast machine 500 kgs

- Bench griders 1 hp

- UTM, Rockwell hardness, etc.,

- Electro Magnet 2 Ton capacity

- ELGI 25 hp screw compressor

- Atlas Copco 25 hp screw compressor

- CNCTurningCenter – F1 – 8”Chuck – Leadwell –Taiwan

- CNCTurningCenter –T6 – 8”Chuck – Leadwell –Taiwan,

- CNCTurningCenter – Doosan Korea

- CNCTurningCenter – Hwacheon Korea

- VMC Machine – 1 No BFW

- Drilling-SPM

- Gantry for automation - Permier evolvics

- Vibro machines

- VerticalBroachingmachine – 1000mm6 ton – SPM –India

- Balancing machine –Abro – Delhi

- Centreless Grinding - 5 –75 mm

- Band Saw Machine

- SlottingMachine - 200mmstroke length – S.V.Panchal

- Power Generator –380 Kva Catter piller & 125 Kva Powerica

- All necessarymeasuring instruments

- Fork lift 3 ton-Ace

- Pallet track

- COIMBATORE METAL WORKS LTD, CBE (High PressureDie casting).

- PERFECT ALUMINIUM ALLOYS, CBE (Manufacturer of Gradedaluminium Ingots).